Curious, detail-oriented, problem-solvers.

Cornerstone Timberframes is continuously learning. As a company, this means we’re always on the lookout for better information, methods, and tools. Our transition towards CNC (computer numeric control), which allows a computer model to directly guide the cutting of timbers, began in 2017 with the acquisition of a used Hundegger K2. We were so impressed with the speed and accuracy of that unit that we upgraded to the latest and best in 2020, a Hundegger K2 Industry with Robot Drive.

I recently sat down with Cornerstone Timberframes’ CNC Team to talk about their work.

Are there skills and interests that you, as CNC operators, share that make you well-suited for the work?

Derek: Being comfortable working with computers is important. Attention to detail is also key because small things, like decimal points, can have a big impact on the result.

Jake: We’re all mechanically inclined and we love knowing how things work. We’re curious and want to know why something happens the way it does.

Matheus: Problem-solving is big. New joinery details will routinely cause error codes and you have to solve them. Figuring stuff out is an everyday part of the job.

Is there any aspect of your work with the K2i that you found surprising?

Derek: The CNC does what you tell it to do and that’s determined by the operator and software. Perhaps one aspect that might surprise someone not doing our work is that the software that runs this machine is constantly being updated. Software updates will solve an issue, but in some cases will introduce a new issue. That happened this past week when an update caused the big 800mm saw to keep spinning after it was done with a cut, which it shouldn’t do. Thankfully, the technicians at Hundegger respond fast, and we get these types of issues resolved quickly.

Mattheus: What I found surprising is this big machine’s ability to cut fine, delicate details. A great example of this is the little trophies we made for a fun competition. We cut them from maple, and the four corner posts are just 3mm thick. I was expecting these would break, but the machine is incredibly controlled and accurate.

Powerful but delicate, the K2i is superb at executing fine details.

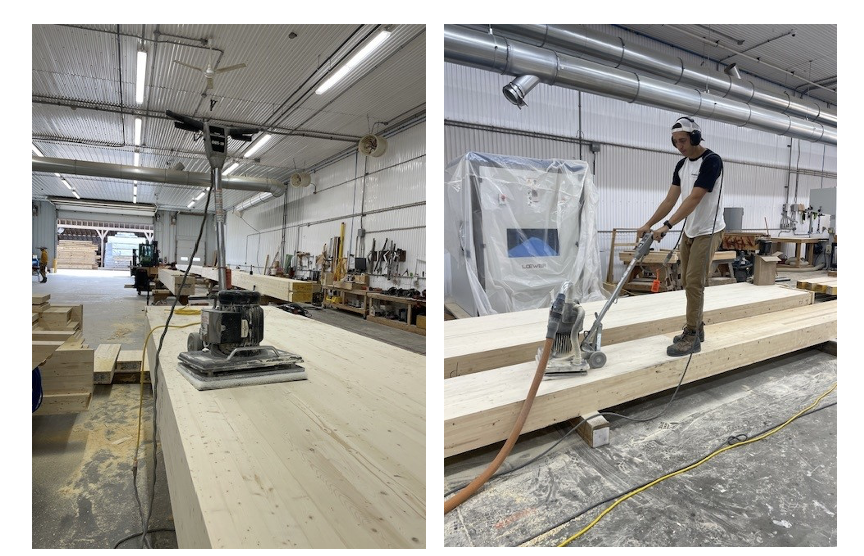

How important is maintenance in your work?

Jake: It’s critical. Every morning all working surfaces inside the machine are cleaned. The CNC spindle and robot drive are lubricated with specific oils. At the same time any replacement blades and tools are also installed. Before regular operation begins a timber is run through with cutting instructions that test the K2i’s many operations to ensure that tools are cutting accurately and cleanly.

Daily tests show that tools are sharp and operating properly.

Does the CNC do everything well, or are there details that are difficult for it to cut?

Mattheus: We have a current job that has lots of round columns and the CNC has trouble seeing and handling rounds. So we “trick it” into seeing these pieces as squares. We attach special saddles to the columns so that the K2i can securely hold and cut them. A few of these columns also need large vee shaped cuts along one side and the K2i can do them, but it takes too long. I think it will go faster if I cut this detail with a circular saw. We’ll see!

Jake: I figure this K2i cuts about 30x faster than a person can. Of course, this also means that if an error makes it through into the final model, that mistake can be cut multiple times before being detected. Focus and checking are super-important.

A lot of our commercial projects use steel brackets, knife blades and connector plates. Timbers, even mass timber beams, are not perfectly uniform and straight, which means that small discrepancies are normal. Combining wood with steel, which has a near-zero tolerance, makes the slots and drillings where these two materials meet especially important and challenging.

CNCs are fast but need creative humans to reach their potential.

What do you see in Cornerstone’s future with respect to CNCs and other tech?

Derek: We’re going to have more technology like CNC’s and robotics, not less.

Mattheus: That’s true, but we’ll also still have timber framing that a CNC won’t do, as long as we have natural and irregular materials like reclaimed barn timbers.

Jake: Machines will do more of the hard, tedious work. CNC’s won’t replace traditional know-how, they’ll replace the hard, repetitive tasks.

Finally, how do you find working together as a team?

Jake: We’re good at solving challenges together. Because we run two shifts, one Monday to Thursday and a second Wednesday to Saturday, communication has to be effective between us – which it is.

Derek: We meet each morning to talk about the day’s tasks. For team members who aren’t here we use emails and shared documents to keep track of details that everyone needs to know.

Mattheus: We enjoy working together. And we learn a lot from each other. Each of us brings our expertise to the work, Derek has lots of previous CNC experience, Jake is an encyclopedia of tools and specifications, and I bring my joinery problem-solving.

After our half-hour conversation, it’s time for the team to get their day underway. I’m feeling guilty knowing how much work is waiting for them. They’re laughing about something as they walk back to their work – a healthy sign of a team that has bonded.

I think about how much our company has changed since we took hold of the potential that CNCs offer. While the technology is impressive, I still find it’s the people that translates that potential into reality. I’m proud of the great individuals and teams that keep Cornerstone at the forefront of sustainable timber construction!