Earthrise 2024

A fresh perspective can be life changing. Fifty-five years ago, this image met the crew of Apollo 8 as they orbited the moon. The astronauts were in awe as they scrambled to find a roll of colour film for Bill Ander’s camera.

The photo that Bill Anders took, shows Earth, set in the vacuum of space above a cratered, lifeless moon surface. How does this image make you feel? What thoughts does it give rise to, about this planet, about life, and your place in it?

For many, an image like this brings up complex feelings: empathy for Earth, a sense that we don’t get how special our home is, that there must be a way for people to treat each other better, that life is beautiful, so fragile, and rare.

All our individual and collective actions speak to how we view our Earth home. On balance, it can be argued that our species has been unkind to the living world and the planetary support systems upon which all life depends. This must change and it’s why we mark Earth Day and consider our role in bringing about positive change.

On a planetary scale, any single action seems trivial, almost worthless. But if we worked ourselves into trouble by a few billion unwise actions, we must find our way out by billions of responsible actions, no matter how small. Everyone has a part.

At Cornerstone Timberframes we’re actively working on several fronts, to bring about positive change. Here’s our Earth Day update on what we’re doing:

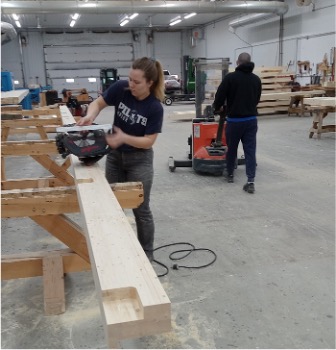

- In 2017 we started working with mass timber, which allows for a low-embodied carbon approach to commercial construction. Mass timber also provides for faster construction while storing large amounts of carbon in the finished building. By 2030 we expect that 75% of our projects will be built with mass timber.

- Our joinery and finishing shops use a lot of electricity – equal to what 44 Manitoba homes need in a year! We’re preparing to go solar. This will free up power during peak daytime hours for use in homes, businesses and in the transition to EV transportation.

- Last year we changed our purchases of engineered wood products to 100% FSC (Forest Stewardship Council) certified wood. This category of wood makes up an increasing share of our production. FSC sets high standards for preserving the forests that provide the timber we use.

- In 2024 we’ll be addressing our wood waste stream that currently needs to be hauled away. We’ll be using it in a high-efficiency boiler to heat our shops, reducing our reliance on electricity, and ending our need for natural gas.

- Cornerstone encourages employees to carpool or use active transport whenever possible. Uptake for both initiatives has been good, but we can still do better. Spring is a great time to tune up our bikes and commit to using the car a little less.

- In March we joined WoodWorks Ontario, the Canadian Wood Council, and the Ontario Forest Industry Association, to visit sawmill and harvest areas in NW Ontario. What we found was inspiring. More First Nations are managing forest lands, deciding how the forests are harvested, renewed, and protected for future generations. The sawmills we visited have more women in leadership roles and more employees from under-represented communities. Welcome changes that move us toward the world we need.

Being good to our planet also brings good things into our lives. Here are a few of our favourite small-scale ideas that Cornerstone employees are working on in their own lives and communities:

- Volunteering at the community bike repair shop. Helping more folks get back onto their bikes, or onto their first bike!

- Planting fruit trees in our shop yard (apple, cherry, pear…). Beauty and food combined.

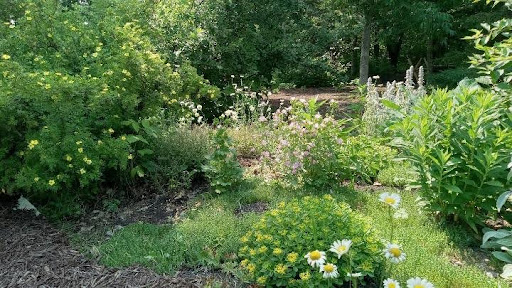

- Replacing more of our lawn with native plantings like highbush cranberry, milkweed, bluestem, gallardia, wild raspberry. It’s amazing how the butterflies find it!

At Cornerstone Timberframes, we believe in using Earth Day as an opportunity to evaluate our practices and strive towards being better. We hope that this inspires you to do the same!