1. Ease of Use

No other construction material is as versatile or easy to use as wood. It can be cut, shaped, and fastened with basic tools. With experienced supervision, installation is quick and can be undertaken by a small crew with only basic carpentry knowledge. Repairs and modifications are easy and do not require heating or other special measures in cold weather.

2. Fire Resistance

Mass timber is inherently hard to ignite, and when exposed to flame it develops a char layer that resists further combustion. Full scale fire testing shows that mass timber can meet and exceed required fire ratings, acting like non-combustible construction. See firetests.cwc.ca for details.

The mass timber demonstration fire test performed as expected, showing the capacity of the burning timber structure to allow for fire decay while surviving full burn-out with this type of fire scenario.

It can be concluded the fire performance of the mass timber structure was similar to that of non-combustible construction in similar fire scenario and confirms that mass timber can perform well under the very rare fire scenario in which the sprinkler system fails and the fire department is unable to respond.

3. Seismic Resilience

Timber can resist seismic forces that cause rigid masonry to crack and crumble. Wood fiber’s elasticity allows it to bend and twist without breaking. Good connection design is critical.

The classic example of seismic performance is the Ying Pagoda in Shanxi, China, built in 1056. It is 67m / 220’ tall and has withstood a dozen major earthquakes over the past millennium. In 1556 (its 500th anniversary) it survived the Jiajing Great Earthquake, the deadliest quake event in recorded history. While built of wood, its exceptional resistance can also be attributed to its design. The Ying Pagoda uses a locking joinery that keeps radial beams in place between the inner core and columns at the outer wall. When things shake and sway these critical connections are designed to move and not break – a flexible, brilliant solution.

4. Acoustic Properties

The International Building Code (IBC) sets out a 50dB sound reduction standard for walls and floors. Concrete, with its high density can achieve this with 15cm / 6” of section. Solid wood is 1/5 the density of concrete, an advantage in almost every aspect of construction, except for resisting sound transmission. Low amplitude sound waves in the 50-100 Hz range are of special concern in floor assembly design with footfalls and furniture movement being the most noted complaint examples in older wood-framed buildings.

Unlike traditional wood frame construction, the draw of mass timber is being able to see the wood. Exposed wood ceilings are especially desirable, and this requires sound insulation to be placed on top of the floor as opposed to it being added into a ceiling void.

A 5-ply CLT floor of 175mm thickness (6 7/8”) by itself has an STC rating of 41. To increase this to a 60 dB rating a multi-layer assembly is required. The top strategies for improving floor sound deadening are:

An updated inventory of STC and ICC ratings with tested assemblies can be found at Woodworks, a US not-for-profit that conducts research on mass timber construction:

Mass timber is an innovative space where new ideas are constantly improving outcomes.

5. Thermal Comfort

Mass timber’s thermal properties are perfectly suited to human use. Mass timber components are slow to transfer heat and cold and help moderate the temperature of indoor spaces even when outdoor temperatures move into extremes.

CLT walls by design and construction are “thermally tight”. In stick framed walls, a common failing is poor draft sealing – air leakage at seams, and at hundreds of nail, staple, and screw punctures, significantly reduces their performance. The CLT’s solid, multi-layer core makes it essentially wind impervious. CLT panels are machined to fit precisely, and simple sealing details ensures a higher fit and finish.

Tests at Oakridge National Laboratory’s Large Scale Climate Simulator showed that CLT walls outperformed stick frame wall assemblies, reducing peak heating and cooling demand by 30%-50% and improving thermal comfort by up to 46%.*

6. Sustainability

Sunlight, soil, and water – that’s the basic recipe for producing wood. Nature excels at making use of available resources, bringing things into balance, while building forest communities whose only “waste products” are oxygen, clean water, and a surplus of beauty.

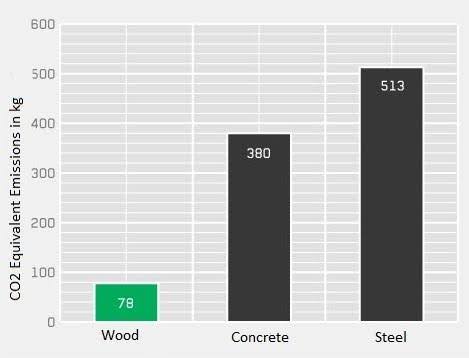

The production of wood and mass timber stand in stark contrast to the energy intensive industrial processes for making concrete and steel. One way to understand and compare these building materials is to examine their contribution to our world’s existential challenge of climate change. Consider the graph below:

This graph compares wood, concrete, and steel, by looking at the CO2 emissions generated in the production of a single beam, designed to span a 7.3m (22’ 3”) distance while supporting a 14.4 kN/m unfactored load. All three materials are optimized to the span and load but achieve it with much different carbon emissions.

The wood beam is a glue-laminated timber made up of responsibly harvested trees. The trees once grew and collected carbon from the atmosphere and now as a wood beam will hold the CO2 for as long as the building exists.

While the decades pass, new trees are growing where the original trees were harvested. With better informed forest practices, the circle of carbon collection and storage can be sustained indefinitely.

7. Speed of Installation

Mass timber structures are fabricated entirely off-site, and deliveries are coordinated to match on-site schedules. Mass timber components assemble quickly and will typically reduce installation schedules by 20-30% over alternative materials.

8. Cost Savings

As mass timber becomes better understood and accepted by architects, engineers, and builders, it is also becoming more cost competitive. In the last two years, studies are showing that an effectively designed mass-timber building is within +/-5% of steel and concrete. With lighter foundation requirements and fast installation, the cost advantage of mass timber will continue to gain market share.

9. Human Health

In Canada and the US, like most of the developed world, the greatest part of our lives is spent indoors. Study after study is showing that the spaces we inhabit play an important role in our physical and emotional wellbeing. Spaces that are enriched by the presence of natural objects and materials are associated with lower levels of stress, feelings of wellbeing, and overall improvements in mental focus and mood.

Wood’s ability to buffer humidity by absorbing and releasing moisture makes for more comfortable homes and offices. Mass timber is chemically inert and uses polyurethane adhesives that do not release VOC’s or other irritants. Studies of mass timber buildings find the use of wood supports better air quality, thermal comfort, visual and acoustic qualities than equivalent structures built with steel or concrete.

11 Main Street – Unit D

Kleefeld, MB R0A 0V0 Canada

4737 County 101 #235

Minnetonka, MN 55345 USA