Indigenous Peoples Day

National Indigenous Peoples Day is this Friday, June 21

This is a day recognizing and celebrating the cultures and contributions of the First Nations, Inuit, and Metis indigenous peoples of Canada.

We’re a tour group of eight: engineers, foresters, and timber advocates – all with open minds but little exposure to Indigenous life, history and worldview. We spent the morning touring the Weyerhauser LSL plant NE of Kenora. The wood supply for this plant comes from land that is managed by a local First Nations resource management company called Miisun. It’s heartening to see First Naitons playing an active role in how their traditional lands are used and protected. It feels like this could be the basis of a mutually respectful relationship.

Our tour guide for the day is Matt Wilkie, Weyerhauser’s local “Purchase Wood & Systems Leader”. He’s a bright light, radiating personal warmth. Matt loves getting people together to share their stories. He wants us to see and experience one of his favourite places: a healing center at Bug Lake called Gamikaan Bimaadiziwin, Ojibwe for, “I will find my life again.”

Caught in cycles of harm or despair a person may reach a point where they know they need help. For First Nations people, the Western ideas of clinical diagnosis, therapy and treatment can offer some relief, but it struggles to reach the deep disconnection and loss that often drive indigenous cycles of harm and pain. Five years ago, Elder Langford Ogemah had a vision for a place where those seeking recovery, could reconnect with their culture, learn skills, participate in ceremony, and draw on the power of the land and their place in it. The program is voluntary and open-ended to meet the unique needs of each person’s journey. And with typical Anishinaabe generosity, the healing center welcomes everyone, whether indigenous or not.

The road into Bug Lake is serpentine and bumpy. As we disembark, we’re greeted by Jackie Marcine and Dave Lindsay. Jackie is a healing guide who exudes a serene energy, while Dave, a Fish & Wildlife Officer for Treaty 3, is exactly the person you’d choose to have with you on a backwoods journey – a kindly teacher-guide, bundled within the power of a bear.

They show us around the camp. It’s mid-day and my stomach is growling. We visit the log yard where a horizontal bandsaw mill will eventually be sheltered under a roof anchored between double stacked sea containers. The mill provides construction lumber for the camp while offering practical skills to program participants.

Three 12’x20’ cabins, a ceremony lodge and a central roundhouse are nearing completion. Architect renderings, on display in one of the cabins, suggests this Bug Lake campus will eventually be able to accommodate 25-30 participants and supporting staff. By the time our tour is done, I’m beginning to feel famished. What greets our eyes as we approach the Round House assures me that my hunger will soon be sated.

Big Kevin, a friend of the Center is here to get the lunch ready. He’s working off a table at the front of the round house, preparing fillets of freshly caught walleye. As we chat the battered fillets are going in and coming out of a pan of hot oil. They smell so good!

When the walleye is done, our group enters the round house, and we make our way to the food table. In my hand is a plate of walleye, a wild rice salad, Bannock, and a green salad. And yes…my mouth is watering.

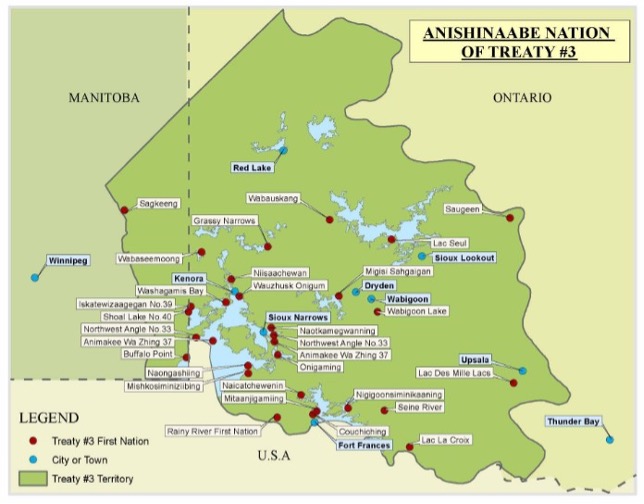

But what’s this, two late guests are arriving. We’re being joined for lunch by Ogichidaa Francis and Betty Kavanaugh, two inspiring, heartful elders of the Treaty #3 nations. Ogichidaa means Grand Chief, and Francis was chosen as Ogichidaa through a traditional discernment process. He’s dedicated 45 years of his life to serving the Anishinaabe Nation in Treaty #3.

It’s a huge honour to have the Kavanaugh’s join us, but my tummy is rudely suggesting I shove a big piece of walleye into my face before going to greet them. I silently thank my mom for the power to resist this discourtesy.

When Francis and Betty are settled with food, we all begin to eat. The food is just too tasty to describe here in a paragraph. During the meal we hear about the history of the region, a people’s struggle to be treated with respect, the need for healing, and a future of shared prosperity and caring for the land. The Anishinaabe of Treaty #3 live in 28 communities sprinkled across an area of 142,000 square kilometers in NW Ontario. That’s an area bigger than Greece or Iceland!

I’m taken with the sense that these are a people who are taking their lives back. They are standing up as equals, bringing special insight into the multi-crisis that confronts all of us. Their message: we need to live in right relationship with each other and the land, and we must partake in loops of reciprocity, responsibility and respect that are the basis of walking a good path in life.

We have much to learn, but I’m filled with hope, as we could not ask for better, more generous teachers.