In this article, we look at a critical but often underappreciated part of timber frames – the roof deck.

In modern timber framing, whether with sawn or mass timber, the roof deck is the first layer that is attached above the ceiling beams or rafters. It’s a big part of what makes timber frames strong and attractive. We call them decks because they’re more than a ceiling finish; they carry roof loads and resist forces that could distort or damage a building.

Tongue and Groove

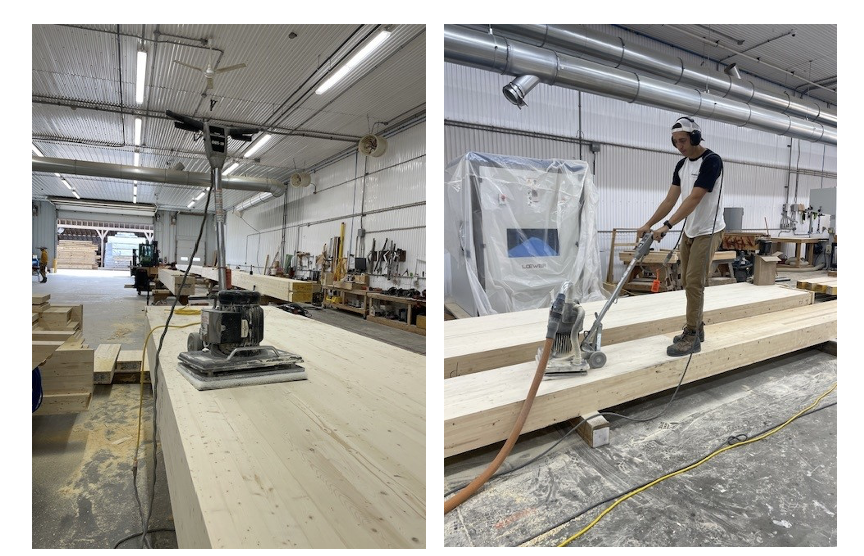

The most popular roof deck material that Cornerstone supplies to client projects is “2×6 tongue and groove boards”, in pine or fir. These boards have a profile that allows them to fit tightly together and span up to 5’ between rafters.

When T&G boards are nailed onto rafters the high friction connection between boards makes the entire roof act as a single unit which can resist lateral forces, such as those created by high winds. They also provide these great benefits:

- Continuous nail base – which means a nail or screw will always find a solid base to attach to. This makes installing the rest of the roof so much easier.

- Work stage – during construction, T&G decking supports workers, making their job faster and safer.

- Interior finish included – not only strong, but also good-looking, T&G boards provide an interior ceiling finish that goes well with timbers.

Tongue and groove boards come in other thicknesses and profiles as well. 1×6 is a favourite for accent walls where the look of T&G is desired but the strength of 2” material would be excessive. And double T&G is made in 3” and 4” formats to be used for spans of 6-8’. It’s harder to find and is often a special-order item that may take 3 months or more to produce.

Mass Timber

Modern and minimalist designs, both residential and commercial, have long spans that require roof decking to match. Laminated wood decking answers this need, coming in 8” and 12” widths and lengths up to 60’. Spans of 10-12’ are typical.

What’s Next

Micro CLT is a fairly new product that is made up of 3 ply’s of laminated wood that run crossways to each other. The material comes in panels, in a variety of dimensions up to 6’ wide by 15’ long. Thicknesses range from ½” to 2-1/4” so it can be used as a wall, ceiling or structural roof deck.

The cross-lamination makes this material extremely stable and strong, while keeping all the beauty of natural wood. Micro CLT often comes with a lap or T&G edge profile, allowing them to fit tightly together. The panel format will enable them to be installed fast!