It’s hard to imagine that a half millimeter could dramatically improve our appreciation of a material. But with a stain or finish, carefully chosen and applied, the natural beauty of wood can go from “that’s nice” to “this is gorgeous!”.

Twenty-one years ago, our CEO opened the first five-gallon pail of stain in Cornerstone’s finishing shop. Her unyielding pursuit of technical perfection is a path our professional finishing team has followed ever since. As Cornerstone entered the world of mass timber our tools and methods adapted. The goal, achieve a super-durable finish that looks great, allows easy clean-up both during and after construction, and makes the owners and occupants proud.

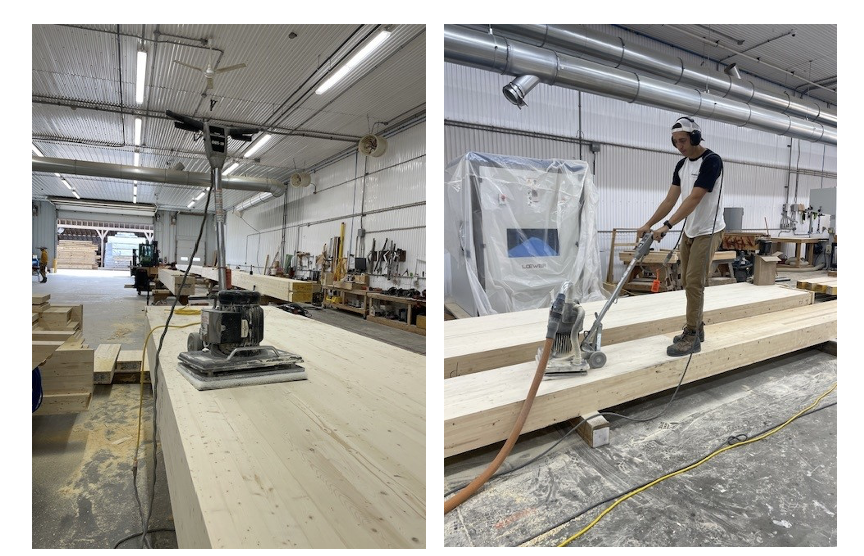

Photo from: Northern Log

One of our first realizations was that mass timber can be very heavy and awkward to handle. Glulam billets that we transform into finished columns and beams can weigh several tonnes and be up to 60’/20m long. Every step of handling requires the right equipment, skilled operators and well considered safety precautions. Moving a 60’ billet through a 24’ wide shop door with a standard forklift simply doesn’t work. Thankfully, a company out of Belfast, Northern Ireland had already solved this problem.

A Combilift Sideloader carries loads to the side of the operator and can drive in all directions, making it an invaluable team member when pieces get long.

Standard industry practice for finishing mass timber is quite basic and consists almost entirely of sprayed wood sealers. These are best described as undercoats, and their stated purpose is “to protect wood from weathering during storage, handling, shipping, and installation”. Sadly, most proponents and owners of mass timber projects never realize the short-term nature of these finishes. Left as the only coating, they leave timbers looking dull, scuff easily and break down within months of application, leaving timbers vulnerable to moisture, UV damage, and dirt.

Cornerstone’s finishing approach is driven by our craft experience. We see mass timber structures like large furniture. They deserve quality finishes that preserve the beauty of an honourable material and that respect the hundreds of hours of craft work in each frame. In our view, a finish must do three things: celebrate the beauty of wood, make cleaning and maintenance easy, and look good for years.

Our finishing process for mass timber follows these steps:

- Billets arriving from the laminator need a good sanding to make them silky smooth

Put the palm sanders away! A set of wide billets gets an initial sanding with…a floor sander.

- A penetrating base coat sets the client’s chosen stain colour into the wood.

- A first topcoat of clear finish is applied to protect the base coat.

- For exterior timbers, a second topcoat is added, providing extensive protection from weather while also enabling easy maintenance.

- The result:

We may be more than a little biased, but the relatively small cost of quality finishing for mass timber is a true no-brainer. So much aesthetic goodness is developed and preserved, while so much hassle and future cost is avoided.

It’s a beautiful half millimetre that should be part of every mass timber plan!