This feisty little tree grows throughout the northern regions of Canada. It survives harsh conditions, long, cold winters, and short 60-day growing seasons.

Black spruce thrives in low, boggy landscapes. It reaches maturity at around 80 years and can live up to 120. Under ideal conditions, it can reach 30 metres into the sky and grow up to 36 centimetres across. But this is rare. Most black spruce will top out at 20 metres (65 ft) and have trunks only 11-15 cm (4-6 inches) in diameter.

Black spruce is well-adapted to wildfires and is one of the first trees to return after a fire. Rather than dropping cones, it holds them in its uppermost branches where they can remain unopened for years. The cones are rigid, resisting weather, squirrels and insects, opening only slowly over time, or quickly when heat from fire softens the cone scales to release the winged seeds.

These cones, held for years, await a fiery dispersal and the start of a new forest.

So far, none of this seems very heroic. In fact, it’s almost surprising that the black spruce is even considered for construction. But here comes a plot twist: small is beautiful, slow is strong, and even early mortality can lead to a new life that saves the day.

Black spruce is the hero. Its list of hardships is now a checklist of preferred traits for sustainable mass timber construction:

- The short growing season faced by black spruce produces tight growth rings, which is ideal for creating high-strength wood fibre.

- The tree has small downward-sloping branches, designed to survive heavy snow loads. Small branches leave only small knots in the milled lumber, which allows it to retain superior strength characteristics.

- It often grows in dense stands and is exceptionally straight. As a result, black spruce boards have straight, uniform grain, giving them exceptional stiffness and stability.

- Black spruce is a short-lived tree which begins to decline in health around age 80. They also stop taking up CO2 and start to release it as they age further. Not surprisingly, this coincides closely with the historic frequency of natural wildfires. Harvesting black spruce before they decline helps to reduce CO2 emissions.

In contrast, large western conifer species like Douglas Fir continue to absorb CO2 throughout their lives and can act as growing carbon sinks for 300 years or more. As a climate-change mitigation strategy, the science makes a compelling case for protecting long-living trees, allowing them to remain in forests to take up and store carbon. At the same time, using black spruce for mass timber is environmentally responsible, as it locks the carbon of end-of-life trees into durable products and reduces the occurrence and intensity of wildfires.

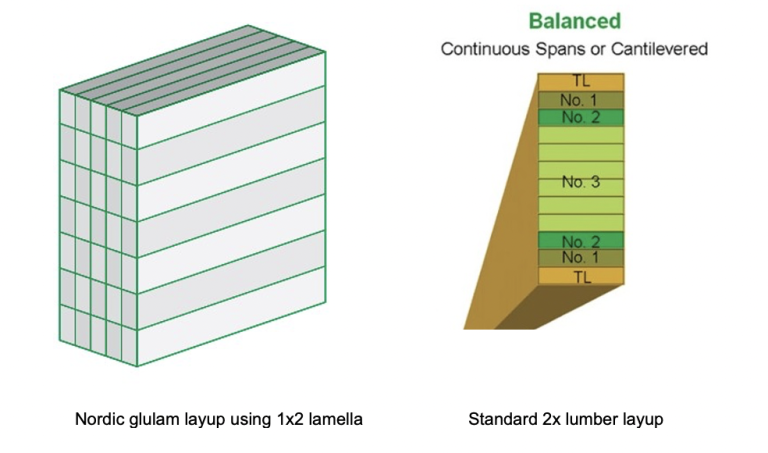

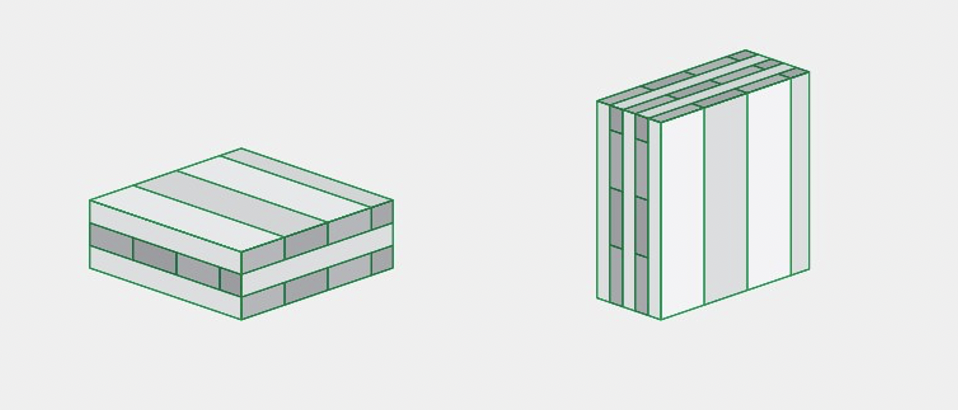

To make mass timber, black spruce requires a passionate and innovative ally. That ally is Nordic’s parent company, Chantiers Chibougamau, which has worked in Quebec’s northern forests since 1961, turning black spruce into lumber and I-joists. In 2000, after years of development and testing, the company introduced the Enviro-Lam process, a method for making large-section glulams out of small-diameter logs. It was a breakthrough that allowed previously unutilized wood fibre to find a high-value use. In 2010, Nordic Structures built North America’s first Cross Laminated Timber (CLT) line and kick-started the continent’s mass timber movement, with black spruce as its undisputed champion.

Understanding and working with nature provides the best innovations and outcomes. When we adapt our approach to fit the resource, both nature and people can thrive.

A section of Nordic Lam+ shows the innovative 30x50mm (1.25”x2”) lamella made possible by the Enviro-Lam process. Also, on display are the impressively tight growth rings that make black spruce such a structural gem.