Meet Our Mass Timber Team

We’re looking forward to the “Mass Timber Group Summit” in Denver, Colorado, July 31 – August 2. It takes place at the Denver Art Museum and will be attended by the leading designers, engineers, suppliers and consultants in the North American mass timber space.

Cornerstone is sending three of our best too, and we’re sure you’ll enjoy meeting our team! As a way to prepare you for some great conversations at the Summit we’d like to introduce you to our mass timber leaders:

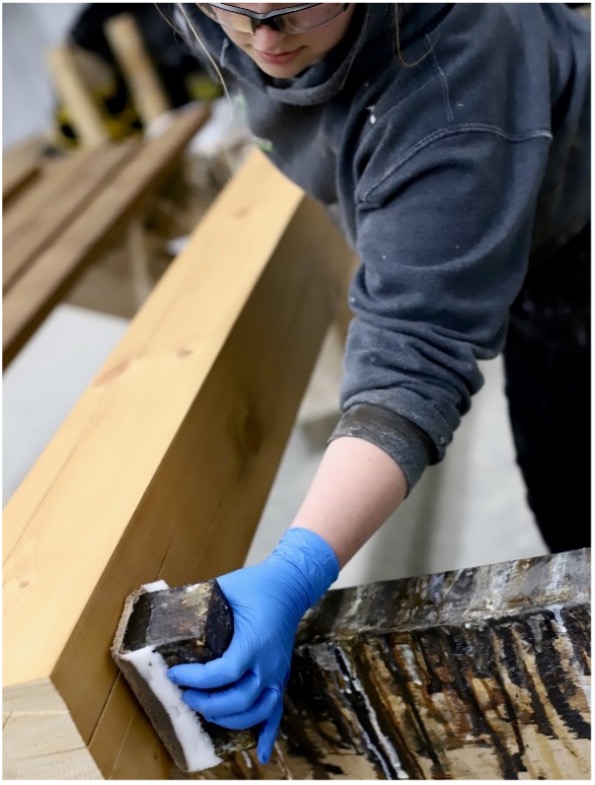

Company CEO, Tanya Bachmeier, is a second-generation owner. She grew up in the business and was instrumental in helping the company adopt digital design for conceptual and shop drawings. She also recognized an unmet need in the heavy timber industry for architectural grade finishes and was amongst the first to offer a fully customized finishing service to clients. (She also plays a mean right wing on the company’s hockey team, the Timberwolves.)

Tanya will be presenting an address to the summit on her personal experience of working in the heavy structural timber industry.

Michael Pankratz, Vice President, studied architecture at University of Manitoba. Following his degree, he sought to better understand the practical aspects of construction and took a job with a firm that worked on everything from high-end custom homes to civic art installations and airport terminals. The diverse hands-on experience of those years cultivated an appreciation of designs that enable ease of construction and efficient site processes. As Cornerstone’s design leader since 2015 he’s been personally involved in all our mass timber projects. (Joins the madness in March when college basketball is in tournament mode)

Michael is presenting a workshop session on a timber wall system that has the potential to simplify our industry’s approach to single and multi-family construction.

Jake Howe, Director of Commercial Sales, hails from Toronto where he attended trades school, learned gas fitting and worked in commercial construction. He went on to pursue his C.E.T. diploma, a Passive House trade certification and worked for one of North America’s largest general contractors. As a project manager he had opportunity to work with mass timber and quickly realized that engineered heavy timber has the power to change the construction industry. (Like many Canadians, he admits to talking loudly to his TV during hockey games.)

Jake will be available with insights as a commercial building project manager in Michael’s workshop.