Our Old “Power Tool” Shop

A high percentage of timber frame joinery work is simply repetitious, and it was rare to find a worker who felt fulfilled doing tedious tasks. (Cutting the 50th mortise pocket is exactly the same as the first!)

Small errors happen regularly: when a circular saw drifts off line, a cut runs a wee bit too far, or layout marks are a little off. Usually nothing big, but occasionally it required a replacement timber to be prepared and cut.

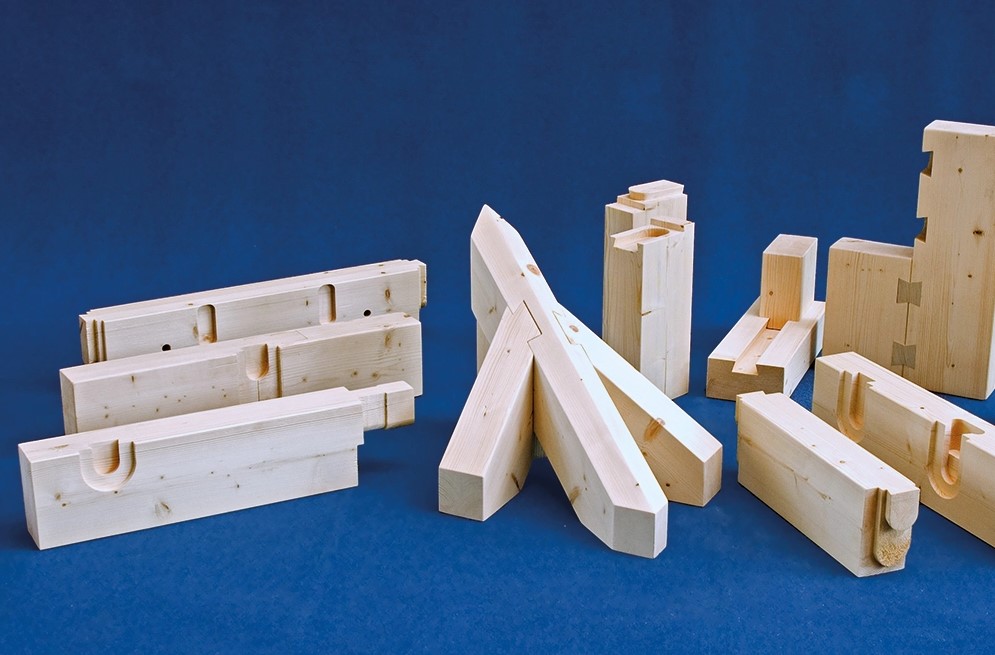

Accurate, tight-fitting joinery is a sign of a well-made timber frame. A lot of work and testing went into adjusting and paring back connection faces to achieve a good fit.

In our old shop we used a wide range of power tools and developed computer models to assist us in making the layout (cut) lines on timbers. Worker attention to detail varied from good to great.

A busy timber frame shop employs up to ten carpenters ranging in skill from novice to master and can produce 2 mid-size frames per month. The “power tool” shop for reasons not fully understood tended to be a competitive, male dominated space.

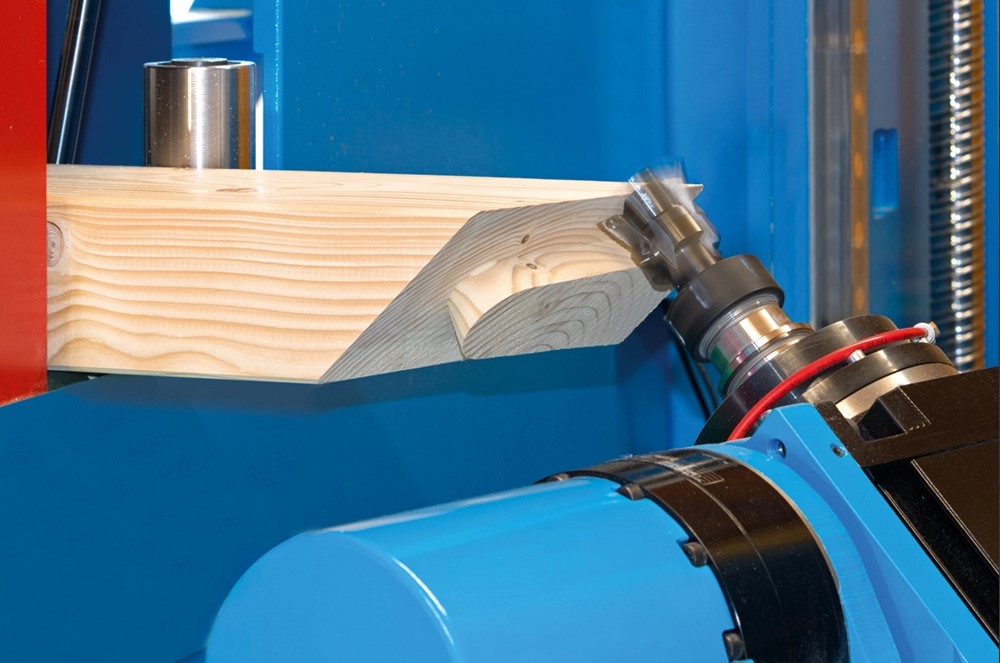

Tapered dovetails were not possible and housed joinery was difficult and time consuming to cut.