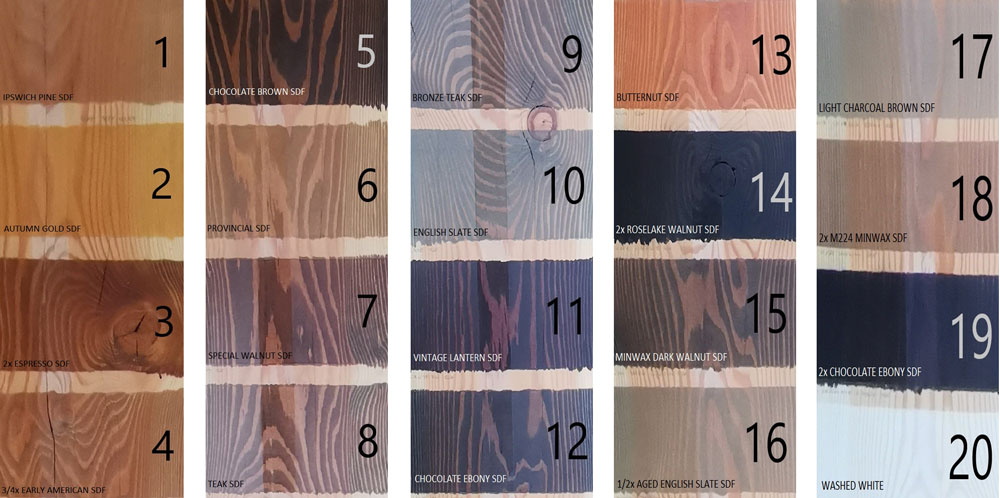

Colour selection

- Collect inspiration images of colours on timber frames that you like. The gallery on this website is a great place to begin.

- Pine and spruce are excellent at taking stain and “play nicely” with the full palette of colours. Fir also takes stain well, but it brings a red undertone that needs to be considered in your choice, and it will limit you to a few less colour options.

- Your choice of flooring and other big, long-term interior features is important to include before making a choice. For outdoor timber, your entry and garage door colours and siding will be an important part of the timber colour discussion.

- When you have the big pieces (above items) on the table, it’s time to start selecting your stain colour. Cornerstone has “starting point” sample boards that show our standard stain colours that cover a range of tones for pine and fir:

- If you don’t find what you’re looking for in these samples, don’t worry, there’s a nearly endless variety of shades and tones that can be explored.

- Clients typically choose 2-4 colours they would like to seriously consider, and these become the basis for the next step…